Scaffolding is an industry of precision, engineering, and safety, but certain quirks often leave professionals scratching their heads. One mystery in particular seems to puzzle everyone at some point: why is a 1.5-inch scaffold tube (or pole) not actually 1.5 inches? If you’ve found yourself wondering about this, you’re not alone!

At B Mat Scaffolding, we pride ourselves on our knowledge and expertise in the field. Today, we’re here to solve this riddle and shed light on other scaffolding curiosities.

By the end of this blog, you’ll have a clearer understanding of scaffold tube dimensions, the standards that guide the industry, and a few bonus insights into scaffolding practices that might have left you puzzled before.

The true diameter of a 1.5 inch scaffold pole

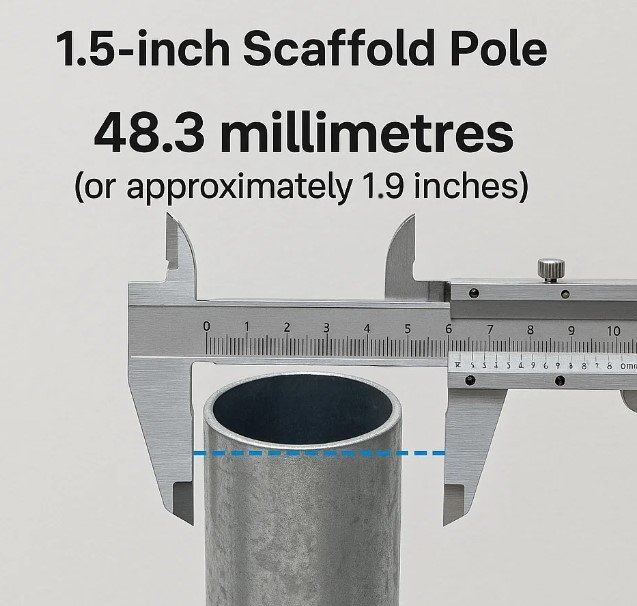

Here’s the short answer to our burning question: a 1.5-inch scaffold pole actually has an outer diameter of 48.3 millimetres (or approximately 1.9 inches), not 1.5 inches as the name suggests. But how did this come to be? To answer that, we need to take a closer look at history and material engineering.

Historical context

The term “1.5-inch scaffold tube” originates from back when tubes were measured using their inner diameter. Decades ago, scaffolding tubes were made with lower-quality steel that required thick walls to achieve stability. These thick walls meant the inner diameter of the tube measured 1.5 inches. It was a naming convention that stuck—but times have changed.

The shift to galvanised steel scaffold

Modern scaffolding uses higher-quality steel, enabling manufacturers to create thinner but equally robust walls. This change means the outer diameter (now the industry standard diameter for measurements) has remained consistent at 48.3 mm, while the inner diameter has grown. The result? A steel tube that, in name, is 1.5 inches but, in actuality, is designed to fit the more precise outer diameter standard.

The adoption of outer diameter standardisation and EN 39

The key to this change is standardisation. Scaffolding systems rely heavily on compatibility between essential components like swivel couplers, clamps, scaffold boards and fittings. The industry now predominantly uses outer diameter measurements to ensure seamless integration, and the European Norm EN 39 ensures a universal scaffold tube outer diameter of 48.3 mm with a minimum wall thickness of 3.2 mm.

By defining scaffolding tube dimensions this way, professionals can avoid the confusing discrepancies that arise when using varying measurement systems, ensuring ease of use and increased safety.

Other scaffolding mysteries solved

Now that we’ve demystified the scaffold tube diameter, it’s time to tackle some other perplexing aspects of scaffolding.

Whether you’re new to the industry or a seasoned veteran, these insights will deepen your understanding.

Mystery 1. the different types of scaffolding and their uses

One common question is why there are so many types of scaffolding, and which one is best for a specific project. Here’s a quick overview of three popular scaffolding types:

- Tube and fitting scaffolding

This traditional method uses tubes, couplers, and boards to create highly adaptable structures. Perfect for jobs that demand high flexibility or unusual shapes.

Best for: Customised configurations and irregular buildings.

- System scaffold

System scaffolds use prefabricated components that fit together for quicker assembly. Popular choices include ringlock and cuplock systems.

Best for: Speed and efficiency on standardised projects.

- Mobile scaffold

These lightweight, wheeled scaffolds are perfect for moving around smaller sites with ease.

Best for: Indoor tasks or smaller construction jobs requiring mobility.

Mystery 2. load-bearing capacities

Another common question revolves around how much weight scaffold poles can handle.

The answer depends on several factors:

- Tube material

Steel scaffold tubes offer high load-bearing capacities compared to lighter aluminium tubes. This allows for heavy loads.

- Inside diameter and outside diameter tube thickness

EN 39 standards require a minimum wall thickness of 3.2 mm for stability. The external diameter should be at least 48.3 mm, with an internal diameter of 40.9 mm.

- Configuration

The arrangement of tubes and couplers impacts how weight is distributed. Incorrect assembly can severely reduce a scaffold’s safe working load.

On average, a properly configured scaffold can safely handle hundreds of kilograms per square metre. However, adhering to specific load charts and conducting assessments is crucial for safety.

Mystery 3. What does steel grade mean?

Steel grade refers to the specific type or quality of steel used in construction. It is often designated by a combination of numbers and letters, such as “Grade A36” or “Grade 316.”

Each grade has different chemical composition and mechanical properties that make it suitable for certain applications (there are also some with a zinc coating which adds additional protection against corrosion). For example, a higher grade of steel may be needed for structures that require greater strength and durability. Steel grades are determined by various standards organizations, such as ASTM International and the American Society of Mechanical Engineers (ASME), to ensure consistency and quality in construction materials.

Choosing the appropriate steel grade is crucial for ensuring structural integrity and safety in buildings and other structures. In scaffolding, using high-grade steel galvanised scaffold tube can also improve the overall stability and load-bearing capacity of the structure, providing a safer working environment for workers.

Other factors to consider when selecting steel grades include corrosion resistance, weldability, and formability. These properties can affect the performance and lifespan of a structure, making it important to carefully evaluate them before making a decision.

Mystery 4. What is the longest scaffold tube?

The longest scaffold tube currently available on the market is typically 21 feet (6.4 meters) long. However, custom lengths can also be ordered for specific projects.

These longer tubes are often used in industrial or large-scale construction projects where a higher reach is needed. They can also be cut into smaller sections to fit different heights and configurations of scaffolding structures.

What this means for you

Understanding quirks like the 1.5-inch scaffold pole mystery, nominal wall thickness and recognising the importance of standardisation isn’t just about satisfying curiosity.

It’s about working smarter, safer, and more efficiently. At B Mat Scaffolding, our goal is to arm you with the knowledge and tools you need to excel.

Whether you’re assembling scaffolding or ensuring compliance with regulations, having reliable, accurate information is key. Our years of experience mean we’ve solved thousands of scaffolding puzzles, big and small, and we’re here to help you do the same.

Ready to take your scaffolding projects to the next level?

Contact B Mat Scaffolding today for expert advice, reliable equipment, and unparalleled support. Whether you’re in need of high-quality materials or guidance on solving a scaffolding challenge, we’ve got you covered.

Get in touch today to find out more and get a free quote for your project.