If you’ve dabbled in construction or worked on any large-scale building projects within the construction industry, you’ve probably come across Kwikstage scaffolding. This modular scaffolding system is a popular choice for its simplicity, durability, and flexibility, but how much do you really know about it? Whether you’re a seasoned scaffolder or a first-timer researching options, this guide covers everything you need to know about Kwikstage scaffolding.

Brought to you by the experts at B-Mat Scaffolding, this blog takes a deep-dive into its components, uses, benefits, and how it compares to other types of scaffolding. Plus, we’ll answer some frequently asked questions around costs, assembly, and more.

What is Kwikstage scaffolding?

Kwikstage scaffolding is a modular scaffolding system designed for temporary support in construction, maintenance, and repair projects. It’s well-known for its ability to adapt to complex building shapes and sizes, offering both stability and versatility.

What sets Kwikstage apart is its ingenious locking mechanism, which makes assembly and dismantling quick and straightforward. It consists of verticals, horizontals, and diagonal braces that connect seamlessly using V-shaped wedges and “Ledgers” (horizontal bars). This productivity-boosting design makes it a go-to solution for scaffolders on a tight schedule while maintaining high safety standards.

Understanding Kwikstage scaffolding

Key components of a Kwikstage system

One of the standout features of Kwikstage scaffolding is its modular design.

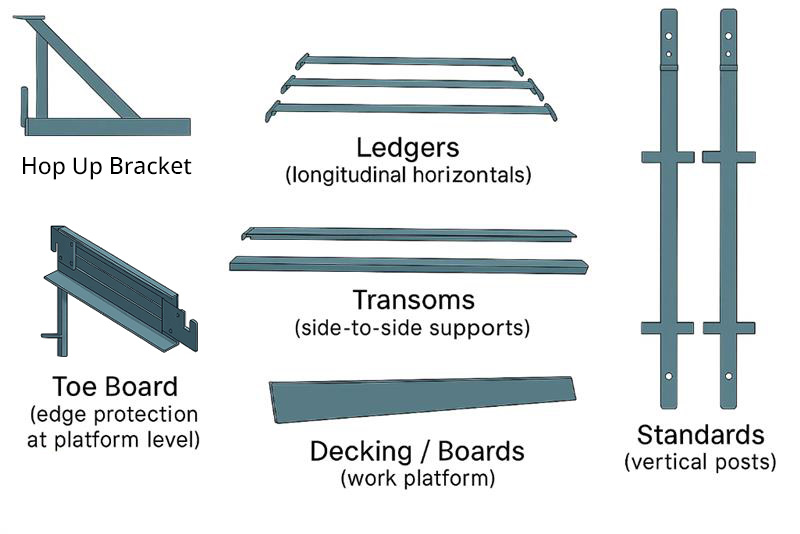

Here’s a quick breakdown of the key scaffolding components:

- Standards (Verticals): These are the vertical tubes comprising multiple “V-pressings” to which other components are fixed.

- Ledgers (Horizontals): Connect standards and serve as the framework for both support and platforms.

- Transoms: Sit perpendicular to ledgers, holding the planks firmly in place.

- Braces: Provide extra stability by connecting diagonally across sections.

- Decking/Boards: These create platforms for workers. Made of either steel or timber, they’re often non-slip for safety.

- Toe boards: Placed on the platforms’ edges to prevent tools or materials from falling off.

Assembly process overview

The modular nature of Kwikstage makes it quick to set up and dismantle — an attractive prospect for many construction operations.

Here’s a brief overview of the process:

- Base preparation: Always ensure the area is level and stable before laying down base plates or sole boards.

- Vertical assembly: Attach standards to the base plates, locking them securely with V-pressings.

- Add ledgers and transoms: Connect horizontal ledgers and transoms to the verticals, creating the platform’s framework.

- Bracing: Add diagonal braces to provide stability to the structure at various levels.

- Decking: Lay planks or metal boards to create sturdy working platforms.

- Repeat and extend: Continue building up as necessary while ensuring thorough checks at every stage.

For safety and efficiency, it’s always best to have trained professionals handle installation.

Applications of Kwikstage scaffolding

Made for versatile projects

Kwikstage scaffolding is widely used in various industries and by many construction workers.

Below are some common projects where its adaptability shines:

- Construction: Ideal for high-rise buildings, residential projects, or architectural structures with irregular designs.

- Maintenance and repair: Perfect for bridges, office buildings, and public infrastructure requiring scaffolding access for cleaning, painting, or restoration.

- Industrial use: Often seen in refineries, factories, and power plants where complex layouts demand a customisable setup.

- Event staging: Beyond construction, Kwikstage systems are often used to create platforms, stages, or seating tiers at events.

Real-life examples

Consider this scenario. You’re working on a heritage church restoration that features curved walls and varying heights. Kwikstage’s flexibility helps create a scaffold structure tailored to these uneven surfaces. Or imagine building a modern office tower where time is money. Its efficient assembly allows you to keep pace with tight schedules.

Kwikstage vs. other scaffolding types

When deciding on scaffolding, you might wonder how Kwikstage stacks up against other types of scaffolding. Here’s a quick comparison:

Pros of Kwikstage scaffolding

- Quick assembly and dismantling: Its modular design and wedge fixing system save time on-site.

- Adaptability: Handles complex and irregular structures with ease.

- Safety: Designed to meet high safety standards and reduce risks during construction.

- Durability: Made with galvanised steel, Kwikstage scaffolding is built to last against the elements.

Cons of Kwikstage scaffolding

- Weight: Being that it is steel scaffolding, it can be heavier than alternatives like aluminium scaffolding.

- Initial cost: While cost-effective over time due to its reusability, it may have a higher upfront cost compared to simpler scaffolding solutions.

A quick overview of other scaffolding types

Cantilever Scaffolding

Cantilever scaffolding is used when the ground does not support vertical standards or when obstacles, such as traffic, prevent the use of regular scaffolding. It involves standards supported by needles, which are anchored securely into the structure.

Double Scaffolding

Double scaffolding, also known as mason’s scaffolding, is primarily used for stone masonry work. It features two rows of vertical supports placed parallel to each other for extra stability, as stone surfaces make it difficult to drill holes for support.

Suspended Scaffolding

Suspended scaffolding is ideal for tasks like painting or exterior repairs on tall buildings. It consists of a platform suspended by ropes or chains that can be raised or lowered to the desired height.

Modular Scaffolding

Modular scaffolding uses pre-fabricated components like frames, braces, and wedges, which fit together in a systematic way. It is widely appreciated for its ease of assembly and adaptability for various construction projects.

Clamp Scaffolding

Clamp scaffolding is constructed using clamps to connect steel or aluminum tubes. It offers flexibility and is commonly used in irregular or complex architectural designs where standard scaffolds are not feasible.

Bamboo Scaffolding

Bamboo scaffolding is a traditional and eco-friendly option widely used in countries like China and India. It is lightweight, cost-effective, and surprisingly strong, often seen in smaller construction or repair projects.

Single Scaffolding

Single scaffolding, also referred to as bricklayer’s scaffolding, is used primarily for brick masonry. It consists of a single row of standards parallel to the wall, along with putlogs that rest in holes drilled into the wall.

Trestle Scaffolding

Trestle scaffolding is another type of single scaffolding, often used for indoor work or when the ground is uneven. It consists of a platform resting on brackets attached to movable ladders or tripods.

Cost considerations

While Kwikstage scaffolding offers exceptional value, its pricing can vary based on project size, height requirements, and rental duration. Click here to check about scaffolding cost.

However, its durability, safety, and ease of use make it one of the most cost-efficient options in the long run.

For a free quote tailored to your project, contact the team at B-Mat Scaffolding.

FAQ

How high can you build Kwikstage scaffolding?

Kwikstage scaffolding can be used for both low- and high-rise projects, typically reaching heights of over 30 metres. However, proper risk assessments and approvals must be in place for higher tiers.

Is Kwikstage scaffolding safe?

Yes! Kwikstage scaffolding is engineered for safety, with a robust locking mechanism, non-slip platforms, and optional guard rails. Regular inspections further enhance safety standards.

Is it reusable?

Absolutely. Kwikstage’s galvanised steel components are highly durable, designed to be used across multiple projects without compromising structural integrity.

Can it handle heavy loads?

Yes. Kwikstage scaffolding is built to support significant loads, making it ideal for both workers and materials. However, always ensure proper weight distribution and adherence to load capacity ratings.

Conclusion

Kwikstage scaffolding is a reliable, versatile solution for construction, repair, and other projects. With its efficient assembly process, robust design, and adaptability, it consistently proves why it’s one of the best types of scaffolding available.

Get your free quote for Kwikstage scaffolding today!

At B-Mat Scaffolding, we’re proud to be industry leaders in scaffolding solutions. Whether you’re undertaking a residential build, commercial project, or something unique, we’ll help you set up the perfect scaffolding system.

Contact us today to enquire about Kwikstage scaffolding and receive a free, no-obligation quote. Together, we’ll ensure your next project is built on a solid foundation.