Scaffolding is an essential component of modern construction. It provides a temporary structure that supports workers and materials, ensuring safety and efficiency.

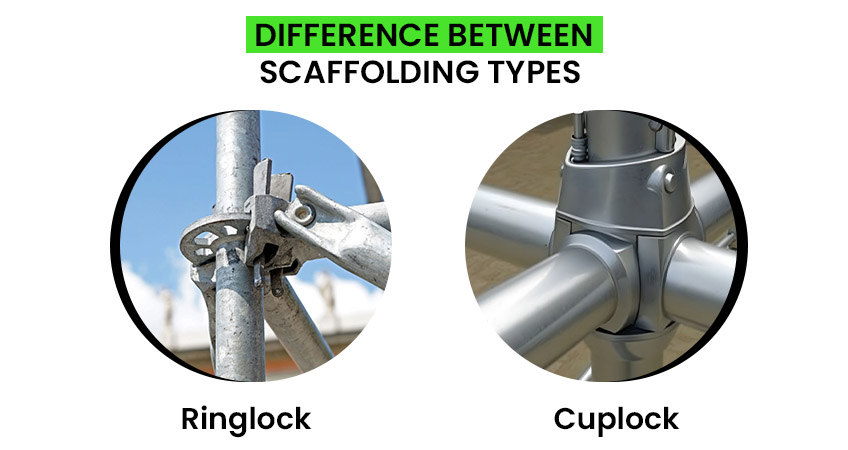

Choosing the right scaffolding system can significantly impact the success of a project. Two of the most commonly used systems are cuplock scaffolding and ringlock scaffolding. While both of these modular system scaffolds are highly effective, they have unique features and advantages that make them suitable for different applications.

This guide explores the difference between ringlock and cuplock scaffolding, providing insights to help construction professionals, project managers, and those seeking scaffolding services make informed decisions.

Understanding scaffolding

What is scaffolding?

Scaffolding is a temporary structure used in construction, maintenance, and repair projects to provide access to high or hard-to-reach areas. Usually consisting of poles and other prefabricated components made from high-grade steel and treated with a minimum zinc coating (allowing for fully galvanized system repair) scaffolding comes in a range of options including single scaffolding, cantilever scaffolding, suspended scaffolding and roller scaffolding (also known as independent mobile towers.)

It ensures workers’ safety by creating secure platforms for tasks like masonry, painting, and renovations. Scaffolding is also used to support building materials.

Modern scaffolding systems, like a cuplock and ringlock system, are modular, making them versatile and easy to assemble. Their modular nature allows for custom configurations suitable for various construction sites.

Safety considerations in scaffolding

Safety is a critical factor when selecting scaffolding systems. A well-chosen scaffold provides stability and reduces the risk of accidents. The design, load-bearing capacity, and assembly process all play a significant role in ensuring safety on-site. Both cuplock and ringlock scaffolding are known for their robust designs and secure assembly mechanisms.

Cuplock scaffolding

What is cuplock scaffolding?

Cuplock scaffolding is a modular system known for its simplicity and versatility. It features node-point connections where vertical and horizontal bars are secured using cup-shaped connectors. This design eliminates the need for bolts and nuts, making assembly quick and straightforward.

Advantages of cuplock scaffolding

- Ease of assembly: The modular design allows workers to assemble and disassemble cuplock scaffolding quickly, saving time and labour costs.

- Versatility: Cuplock scaffolding adapts easily to different project requirements, including straight structures and intricate designs.

- Load-bearing capacity: Its robust design can support a large number of workers and construction materials, making it ideal for heavy-duty tasks.

- Stability: The wedge-locking mechanism ensures a secure and stable structure, minimising the risk of accidents.

- Cost-effective: Quick assembly and disassembly reduce labour costs, and the scaffold’s durability ensures long-term value.

Ideal applications for cuplock scaffolding

Cuplock scaffolding is commonly used in projects that require stable and adaptable structures, such as:

- High-rise building construction

- Industrial facilities

- Maintenance tasks

- Masonry projects

Ringlock scaffolding

What is ringlock scaffolding?

A ringlock scaffolding system is another modular offering that has gained popularity for its efficiency and flexibility. Instead of cup-shaped connectors, it uses rosette-type connectors to join vertical and horizontal bars. This versatile design allows for multiple configuration options, making it suitable for complex geometries.

Advantages of ringlock scaffolding

- Flexibility in design: The rosette system enables precise alignment and configurations for challenging projects and complex structures.

- Ease of assembly: Like cuplock, ringlock scaffolding is simple to set up and dismantle, saving time and effort.

- Stability: This robust system provides an optimised structure with notches for secure locking, ensuring stability even at great heights.

- Load capacity: Its design efficiently distributes weight, making it suitable for heavy-duty applications.

- Space-saving: Ringlock components are lightweight and compact, making them easy to transport and store.

Ideal applications for ringlock scaffolding

Ringlock scaffolding is ideal for projects requiring advanced configurations and high load capacities, such as:

- Infrastructure projects (e.g., bridges and dams)

- Complex construction designs

- Maintenance and renovation tasks

- Formwork systems in construction

Cuplock vs ringlock scaffolding

Key differences

| Feature | Cuplock Scaffolding | Ringlock Scaffolding |

|---|---|---|

| Assembly mechanism | Cup-shaped connectors | Rosette-type connectors |

| Flexibility | Suitable for straight and simpler structures | Allows for advanced configurations |

| Load-bearing capacity | High load capacity | Higher load capacity and better weight distribution |

| Ease of assembly | Quick assembly with fewer components | Lightweight parts for easier handling |

| Applications | Versatile and commonly used for standard projects | Ideal for complex and heavy-duty projects |

| Cost | Generally more cost-effective | Slightly higher cost due to advanced features |

Use cases

- Cuplock scaffolding is perfect for straightforward projects requiring stable and cost-effective solutions.

- Ringlock scaffolding excels in complicated building geometries that require flexibility and high load capacities, such as large-scale infrastructure projects.

Difference between cuplock and ringlock in real-world examples

Cuplock scaffolding in action

A company within the construction industry recently used cuplock scaffolding for a multistory apartment project. The quick assembly reduced labour costs, while the system’s load-bearing capacity supported multiple workers and heavy materials. The wedge-locking mechanism provided much-needed stability.

Ringlock scaffolding in action

A bridge renovation project relied on ringlock scaffolding for its flexibility and load capacity. The rosette connectors allowed the team to configure the scaffold around the bridge’s intricate design, while its stability ensured safe working conditions at great heights.

Making the right choice for your project

Selecting the best scaffolding system depends on the specific needs of your project. Cuplock scaffolding is ideal for simpler, cost-effective solutions, while ringlock scaffolding is better suited for complex and heavy-duty applications.

At B-Mat Scaffolding, we’re here to guide you through the decision-making process. With our expertise and high-quality scaffolding systems, you can ensure your project’s success while maintaining the highest safety standards.

Get in touch with B Mat Scaffolding today

Looking for advice or to purchase cuplock scaffolding or ringlock scaffolding?

Contact B-Mat Scaffolding today to learn more about our wide range of scaffolding solutions and get a free quote. Our experienced team is ready to help you select the perfect system for your project.