Scaffolding is the backbone of countless construction work and renovation projects, providing secure access to elevated areas and supporting workers as they bring designs to life. While scaffolding itself is critical, the tools used to assemble, maintain, and optimise these structures are just as important. Without the right equipment, even the most skilled scaffolder would find themselves at a disadvantage.

Whether you’re a construction professional, a project manager overseeing a number of construction sites or construction projects or someone hiring a scaffolding company, understanding the essential tools and equipment used in scaffolding ensures safe, efficient, and compliant projects.

This blog will guide you through the tools, materials, and modern solutions that are pivotal to high-quality scaffolding work.

Why quality tools matter in scaffolding

Scaffolding is inherently a high-stakes operation (no pun intended). The wellbeing of workers depends on structures that are stable and reliable, so investing in the right tools and materials isn’t optional—it’s essential.

Using subpar equipment can lead to errors, downtime, and even catastrophic accidents, while top-quality tools increase efficiency and ensure compliance with health and safety standards.

Key benefits of using the right tools include:

- Improved safety: Properly assembled scaffolding reduces risks of instability and collapse.

- Faster assembly: Professional-grade tools are designed for speed and precision.

- Cost-effectiveness: Quality tools last longer and require less maintenance, saving money over time.

Now, let’s look at the essential scaffolding tools and equipment that no professional can work without.

Essential scaffolding tools for every job

Every scaffolding professional relies on a core set of tools. Here are the must-haves:

1. Scaffolding wrenches and ratchets

Scaffolding wrenches and ratchets are indispensable for tightening bolts and couplers that bind scaffold structures together. Loose fittings can compromise the integrity of the scaffold, so having reliable, durable wrenches is non-negotiable.

2. Impact drivers

Time is money in construction, and impact drivers dramatically cut down the time it takes to assemble structures. These tools are particularly useful when working with metal scaffolding, where additional torque speeds up assembly without compromising on quality or safety.

3. Levels and measuring tapes

Precision is at the heart of scaffolding. A spirit level ensures that scaffolds are perfectly vertical and horizontal, while a measuring tape allows for accurate dimensions during assembly. Together, these tools help ensure the scaffolding is safe and structurally sound.

4. Base plates and adjustable jacks

A secure foundation is crucial for stability. Base plates distribute weight evenly, while adjustable jacks compensate for uneven surfaces, ensuring the scaffolding stands level and supports the load effectively.

5. Working at height safety equipment (guard rails and safety nets)

When working at heights, guard rails provide a physical barrier against potential falls, while safety nets act as an additional precaution, protecting workers below. These components are vital for ensuring compliance with health and safety regulations.

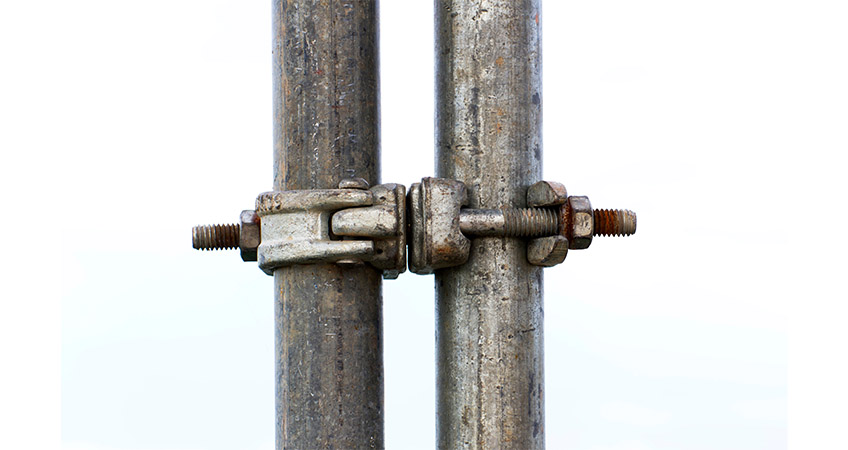

6. Couplers and clamps

Couplers and clamps are the unsung heroes of scaffolding. These small components secure tubes and scaffolding boards in place, holding the entire structure together. Using high-quality couplers ensures long-lasting, stable scaffolding.

Choosing the right materials for scaffold structures

Beyond the tools used, the materials chosen for scaffolding structures are equally significant. The two most common materials in scaffolding are galvanised steel and aluminium, each offering specific benefits:

- Galvanised steel: Known for its strength, steel scaffolding can handle heavy loads and withstand tough environmental conditions.

- Aluminium: Lightweight and easy to handle, aluminium scaffolding is ideal for projects requiring frequent assembly and disassembly.

Investing in robust materials ensures the durability and reliability of the structure, reducing the risk of failure over time in different types of scaffolding.

Skilled personnel are just as important as tools

Even the best tools and materials can’t compensate for a lack of expertise. Skilled scaffolders must be trained and certified to ensure they operate efficiently and safely. Proper training helps workers:

- Understand how to use tools and materials correctly.

- Ensure compliance with legal health and safety standards.

- Identify risks and mitigate hazards effectively.

At B-Mat Scaffolding, every member of our team undergoes rigorous training and holds the necessary certifications to deliver safe, top-tier results consistently.

How technology enhances scaffolding projects

The scaffolding industry is no stranger to innovation. Advanced technologies like smart scaffolder software are transforming the way scaffolding projects are planned and executed. These tools provide numerous benefits, including:

- Improved planning: Design scaffold layouts and generate quotations quickly and accurately.

- Enhanced safety: Identify potential risks during the planning phase.

- Clearer communication: Share real-time updates and instructions amongst team members.

By integrating modern technology into scaffolding projects, companies like ours streamline operations and deliver results more effectively.

Why investing in the right tools and scaffolding equipment is worth it

When managing scaffolding projects, cutting corners on tools or materials is a false economy. Investing in top-tier equipment and staying updated with the latest technological advancements ultimately results in:

- Faster completion times.

- Reduced safety risks.

- A better return on investment.

At B-Mat Scaffolding, we pride ourselves on using the best tools and technologies available, ensuring our clients receive nothing but the highest standard of service.

Conclusion

Using the right tools and materials is paramount to ensuring scaffolding projects are safe, efficient, and successful. From essential hand tools like wrenches and levels to advanced technologies like smart scaffolder software, every component plays a vital role in delivering outstanding results.

Get a professional scaffolding solution today with B-Mat Scaffolding

If you’re planning a scaffolding project, partnering with professionals who prioritise quality tools and skilled personnel makes all the difference. At B-Mat Scaffolding, we combine cutting-edge equipment with expert knowledge to support projects of all sizes—commercial or residential.

Our services are supported by comprehensive accreditations, including Gold membership with Constructionline, CISRS qualifications, and CHAS approval.

Contact us today to discuss your scaffolding needs and discover how we can make your project a success.