System scaffolding has revolutionised the construction industry, offering a safer, quicker, and more versatile alternative to traditional scaffolding methods. From construction sites to industrial applications and even event staging, system scaffolding is proving its worth in a range of diverse scenarios.

But what exactly is system scaffolding? How does it work, and why is it gaining popularity in various industries? This comprehensive guide by B-Mat Scaffolding will walk you through everything you need to know about system scaffolding—from its components and advantages to best practices and future trends.

What is system scaffolding?

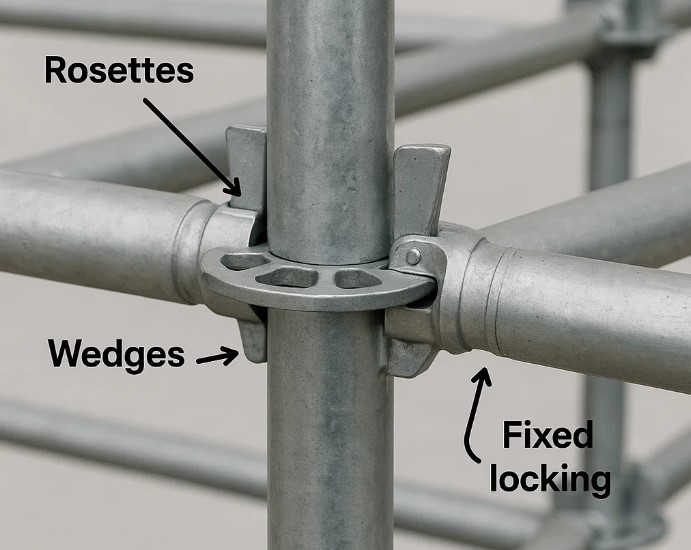

System scaffolding is a modular scaffolding system consisting of pre-engineered components and connection points designed to interlock seamlessly. Unlike traditional scaffolding, which requires loose fittings like clamps and couplers, system scaffolding pieces connect with rosettes, wedges, and fixed locking mechanisms. Think of it as the LEGO or K’NEX of scaffolding.

A brief history of system scaffolding

System scaffolding has its origins in the mid-20th century when engineers sought faster and safer alternatives to the traditional tube-and-fitting scaffolding structure. Over time, its design evolved to integrate user-friendly features such as interlocking parts, enhanced stability, and minimal loose components. Today, system scaffolding is a go-to solution for many industries due to its efficiency and adaptability.

Components of system scaffolding

A full understanding of system scaffolding starts with breaking it down into its core components.

Each part serves a specific purpose, ensuring a sturdy and adaptable structure.

Standards (Vertical supports)

Standards serve as the primary structural base, running vertically. They feature rosettes or rings along their length, allowing other components to connect securely.

Ledgers (Horizontal supports)

Positioned horizontally, ledgers provide stability and act as handrails or barriers, depending on their placement.

Transoms (Intermediate supports)

Transoms slot into ledgers and standards to form the working platform. They enhance lateral strength and distribute the weight of the planking.

Braces (Diagonal supports)

Braces ensure the scaffold’s stability by maintaining its rigidity. These diagonal elements prevent unnecessary movement or vibrations during use.

Base collars and adjustable bases

The base collars form the foundation of the scaffolding tower, while adjustable bases allow for height manipulations to accommodate uneven surfaces.

Planks or decks

Made from steel or aluminium, the planks or decks create the platform on which workers operate. Their slip-resistant surfaces enhance worker safety.

Advantages of using system scaffolding

System scaffolding offers benefits beyond traditional solutions. Here’s why it’s becoming a staple across industries.

Faster assembly and dismantling

The pre-engineered design simplifies assembly, reducing labor hours and, more importantly, labor costs. Contractors can often erect a system scaffold in less than half the time needed for traditional scaffolding.

Enhanced safety features

Each component interlocks securely, minimising errors and hazards. Its design also eliminates the risk of loose fittings falling mid-project. The modular nature also makes it quicker for each component to be checked at regular intervals for damage or defects and be replaced if necessary.

Versatility and adaptability of the scaffolding system

With modular components, system scaffolding can be configured for various heights, widths, and shapes, making it ideal for diverse applications.

Cost-effective

Due to faster assembly and reduced material waste, system scaffolding saves both time and money, providing excellent value for any project.

Superior load-bearing capacity and structural integrity

The robust engineering allows system scaffolding to support higher loads while using fewer components than traditional scaffolding.

Reduced environmental impact

High-quality materials and reduced waste generation make system scaffolding a sustainable choice. Steel and aluminium components can often be reused, extending their lifespan.

Where system scaffolding can be used

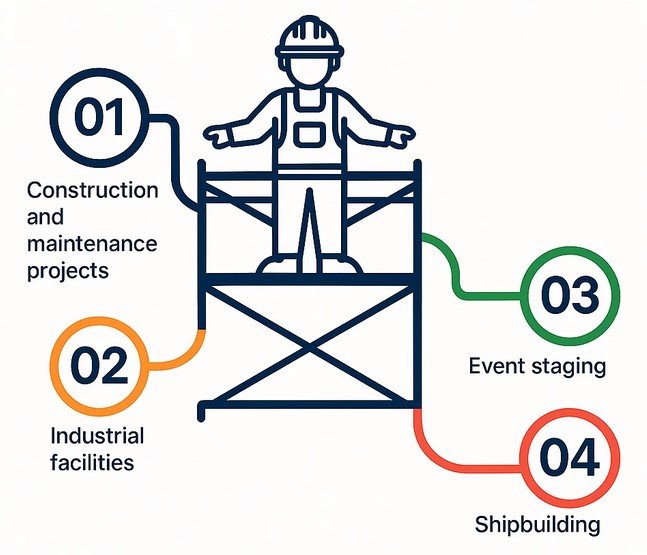

System scaffolding is not limited to construction sites.

Its adaptability means it has various applications makes it suitable for an array of industries.

Construction and maintenance projects

From residential builds to large-scale infrastructure, system scaffolding provides dependable support for a variety of tasks.

System scaffolding is easily adjustable and therefore perfect for maintenance projects, especially those requiring tricky angles or reaching confined spaces.

Industrial facilities

Factories, refineries, and industrial plants benefit from system scaffolding’s strength and safety, particularly in high-traffic areas.

Event staging

Concerts and exhibitions require quick setup and tear-down processes, and system scaffolding delivers both speed and stability.

Shipbuilding

The maritime industry relies on system scaffolding for ship repairs and maintenance due to its ability to adapt to curved surfaces.

Some of the different types of system scaffolding

Supported system scaffolding

Supported system scaffolding, also known as frame or prefab scaffolding, is the most commonly used type. It consists of vertical and horizontal frames connected by braces and ledgers to create a stable structure. This type of scaffolding can be adapted to various shapes and sizes, making it suitable for a wide range of projects.

Suspended system scaffolding

Suspended system scaffolding, also known as suspended scaffold or swing stage, is used for projects that require workers to have access to areas at different heights. This type of scaffolding is supported by ropes attached to the top of a building or structure and can be raised or lowered using pulleys. It is often used in construction, maintenance, and repair projects on high-rise buildings or bridges.

Suspended scaffolding offers flexibility and allows workers to access hard-to-reach areas. It also provides a stable working platform for multiple workers at once. However, it requires proper training and maintenance to ensure the safety of workers as they are suspended in the air.

Mobile scaffolding

Mobile scaffolding, also known as rolling scaffold or tower scaffold, is a type of scaffolding that can be easily moved around a job site. It consists of a frame with wheels and casters attached to the bottom for mobility. Mobile scaffolds are commonly used in indoor settings such as warehouses and factories, but can also be used outdoors.

Comparing system scaffolding to traditional scaffolding

Wondering if system scaffolding is better for your needs? Here’s a quick comparison.

| Aspect | System Scaffolding | Traditional Scaffolding |

|---|---|---|

| Assembly method | Modular components with interlocks | Labour-intensive with loose fittings |

| Safety | Enhanced locking mechanisms | More potential for component failure |

| Cost-efficiency | Reduced labour costs | Higher setup costs |

| Applications | Versatile, ideal for complex jobs | Best for simple structures |

Conclusion

When choosing between system scaffolding and traditional scaffolding, it’s essential to consider the specific requirements of your project. System scaffolding stands out for its ease of assembly, enhanced safety features, and cost-efficiency, making it ideal for dynamic and complex applications.

Meanwhile, traditional scaffolding can still serve as a reliable option for simpler structures. By assessing your project’s complexity, budget, and safety needs, you can make an informed decision that ensures both efficiency and success.

Partner with B-Mat Scaffolding

At B-Mat Scaffolding, we specialise in system scaffolding solutions tailored to your needs. With decades of experience and a commitment to safety and excellence, we’ve built a reputation as industry leaders.

Whether you’re planning a construction project, industrial repair, or event staging, we’ll help you get the job done safely, efficiently, and cost-effectively.

Contact us today

Get in touch with B-Mat Scaffolding to learn more about our services and how we can elevate your next project.